In some cases, I give a few tips on how to make the turning for others, I give a nod to the turner who inspired the piece, or some advice on suitable woods to use.Įighty patterns doesn’t begin to cover everything that can be made on the lathe.

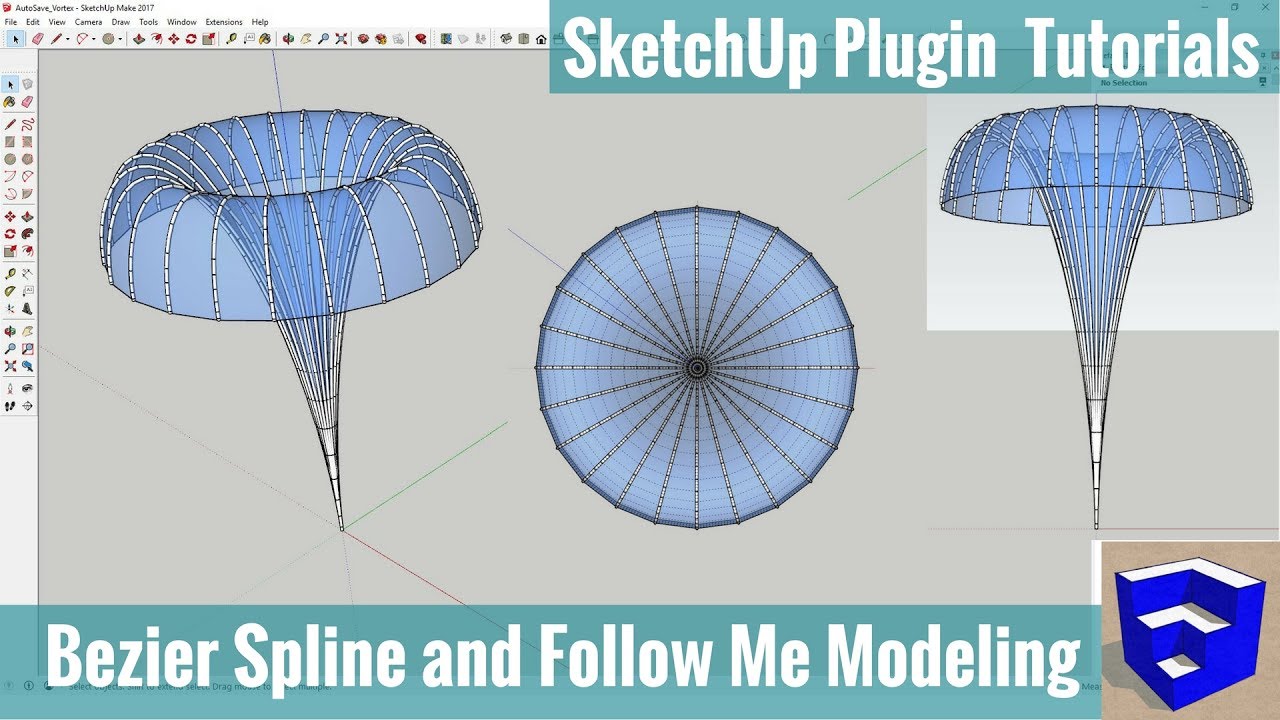

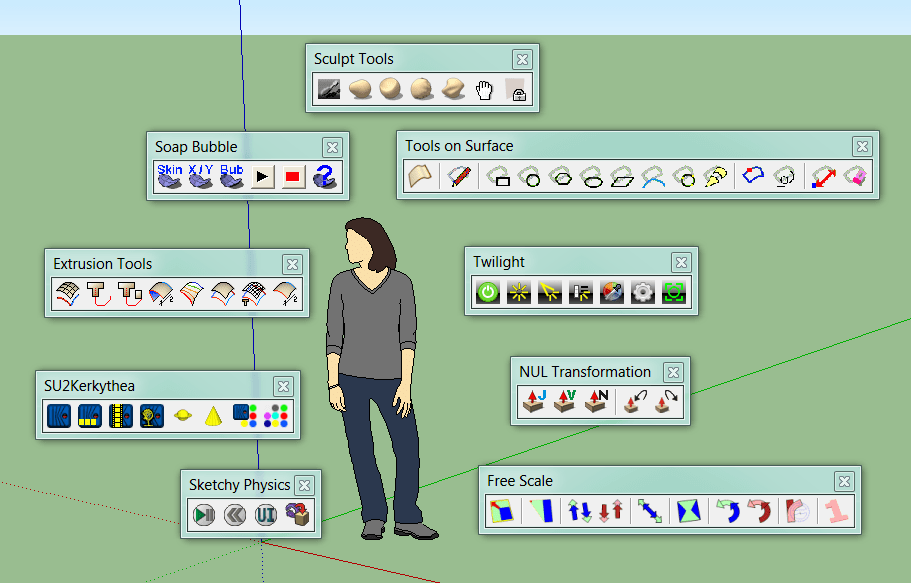

Once I had the pattern in place, I’d type in a title and a couple of paragraphs of text. Because my LayOut template and the InDesign template used the same page size, I never had to worry that the drawings would be out of scale. (The publisher wanted me to deliver the book as an InDesign file.) The two-page template I created put text on the left and the jpeg of the pattern on the right. Into InDesignįor the last step of the process, I switched to InDesign, Adobe’s page-layout program. Once I had completed the dimensions on the profile and positioned the extrusion on the LayOut page, I exported the file as a high-resolution jpeg. I also took advantage of LayOut’s clipping mask function to produce inset images enlarged for clarity. LayOut made dimensioning the patterns easy and accurate. Whatever the inspiration for a pattern, I began by taking careful measurements from the piece itself, or by importing an image into SketchUp, scaling it to actual size, and using measurements from the image as a basis for modeling. And pieces by Richard Raffan, one of the finest turners working today, gave me the starting point for a baby rattle and a serving platter. I did the same for a salad-bowl set, working from designs by the late Bob Stocksdale, a very influential woodturner in Oakland, California. I used it as the inspiration for one of the patterns. Rude Osolnik, who taught for decades at Berea College, in Kentucky, created an iconic midcentury-modern candlestick. In effect, I used pattern books to come up with some patterns for my book.įinally, I looked to some of the giants of woodturning for inspiration. My library yielded more patterns, for knobs, finials, and some bowls.

I needed to be sure that the handle designs I created would mate nicely with the metal parts. Those items have a short metal shaft that’s glued into a hole in the turned wooden handle. (Ed note: Go figure!)įor pepper mills and other kitchenware, I tracked down sizes for the grinding mechanism as well as typical specs for pizza cutters, cheese slicers, and the like. But I also learned that the organizations in charge of croquet offer a lot of latitude for the size of the mallet head. There are very precise specifications for a regulation baseball bat, for example. Other pieces required some Internet research. A three-sided tool handle that I made for myself also became one of the patterns in the book.

0 kommentar(er)

0 kommentar(er)